Plastic Caps & Closures Visual Inspection System

- The latest KeyeTech AI visual inspection system algorithm for multiple appearance defect detection of plastic caps & closures.

- Full automatic high speed caps & closure inspection system with the maxim inspection speed 2500pcs/min.

- High compatibility with more various inspection product kinds, different outlines, colors and sizes tolerance.

- Easy operation for new defect inspection solution by remote maintenance and self-developed AI cloud platform.

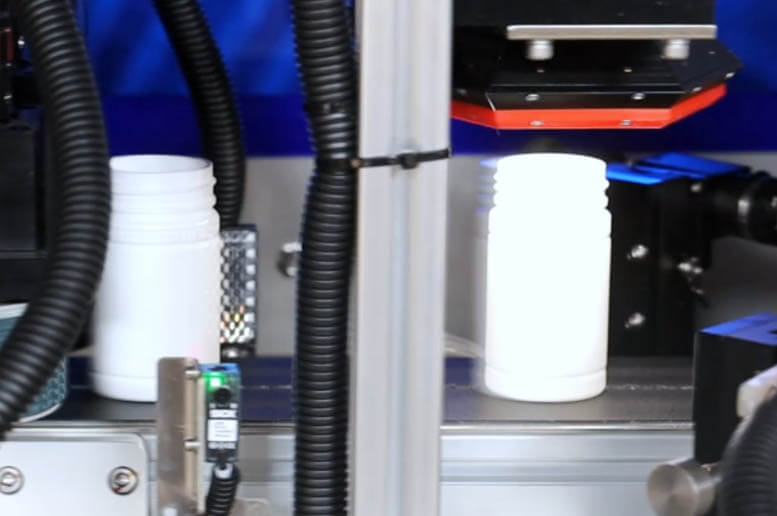

Bottles & Containers Visual Inspection System

Customize your inspection project properly

Adopt the latest KeyeTech AI visual inspection system for most kinds appearance defects of plastic bottles and containers.

In-line & off line inspection for various plastic bottles with maxim speed of 300pcs/min, widely used for pharma, beverage, dairy industries.

Design the most suitable visual inspection solution based on the user's bottle material, shape, and defect detection needs, to ensure quality control for plastic bottle production factories and save production costs.

Applications

About KeyeTech

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer of visual inspection system, It can provide the most advanced level AI algorithms and the customized solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries. The company was established in 2011, it has a high-level R&D doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. We focus on visual inspection solutions in plastic packaging industries, till 2023 we already served more than 2000 customers both for domestic and abroad market, our products can be applied in food & beverage, pharmacy, dairy package, daily chemicals, electronic components, new energy, agricultural product, etc.

Core Advantageous Technologies

Core Doctoral R&D Team

The core R&D personnel of the company in optics, software, mechanics, electronics, and algorithms are all senior PhDs in the industry, with many years of experience in research and application in the field of vision field, all the members of our doctoral team are from USTC.

Self-Developed Modularization Computing Box

The latest modular control unit can effectively replace traditional PLC control systems, with 32TOPS NPU chip, faster computing power and the ability to adapt to harsher environmental temperatures and humidity, ensuring data loss in the event of sudden power outages.

Remote Operation & Maintenance Support

Our software and systems can be updated online as long as it is connected to the Internet. We can make adjustments to the application terminal at any time according to customer requirements. Customers can also achieve 7X24 remote after-sales service through the AI cloud platform.

Advanced Self-Developed AI Algorithms

KeyeTech has a professional algorithm research and development team of 15 people, which can better ensure the progressiveness and sustainability of AI technology, and provide customers with more intelligent algorithm systems and better detection results.

Self-Developed Hardware & Software

Our hardware team provides us with customized light sources and imaging systems that can better integrate our proprietary algorithms. At the same time, our software team continuously optimizes our control software to make operation and use more convenient and simple.

Customized Optical Imaging System

Based on our R&D team with a full technical chain, we can design corresponding detection software and hardware more flexibly according to the product characteristics and detection needs of different customers, such as image display, data transmission to export, signal linkage, etc.

Who Choose KeyeTech?

Employee

The largest visual equipment enterprise in China

R&D Team

The number of R&D people count for more than 30%

Partner

More than 2000 partners in domestic and abroad

Area

The largest single vision manufacture center

Contact Us

FAQs

KeyeTech is a professional manufacturer of visual inspection machinery, established in 2011. We are the first company who applied AI technology into vision inspection area.

To proceed with the customized machine, kindly provide us with your requirements such as product details (picture,layout), inspected defect types, inspection speed, in-line or off line, as well as treatment way of the defective products, etc.

First of all, we are the manufacturer & designer of visual inspection equipment only, we have the complete R&D technology chain covering optics, algorithm, electrics, mechanics, software. We can support high level customization inspection system and meet high compatibility inspect request.

Production period is not fixed, for the normal standard product we have semi-product in stock, we can finish the production within 2~3 weeks, for the complicated customized machines it may take more than 8 weeks, so, the exact delivery time is depend on the customer’s requirement details.

KeyeTech has a very comprehensive quality control system. Before the production of the system, each department will conduct technical audits. After production is completed, the company has a dedicated testing team to test the equipment. Only when it meets customer testing requirements will it be arranged for shipment.

One year warranty for quality with lifelong service available.