Exciting Launch! KeyeTech Achieves New Breakthrough in Defect Generation

In industrial production lines, high-quality defect data is crucial for training and optimizing AI visual inspection models. Obtaining rare, high-quality defect samples for product appearance defect detection requires multi-layered efforts. is an inevitable trend.

Manually creating product defect samples—low authenticity!

High yield rates and low defect rates, collecting defect samples online—time-consuming!

Changing product types and collecting a large number of defect samples in a short time—challenging!

Complex and diverse sample defects, cumbersome collection—inefficient!

To address the scarcity of sample datasets and the difficulties in collection, KeyeTech proudly presents its innovative solution: the “Intelligent Defect Generation Technology“!

KeyeTech’s “Defect Synthesis”

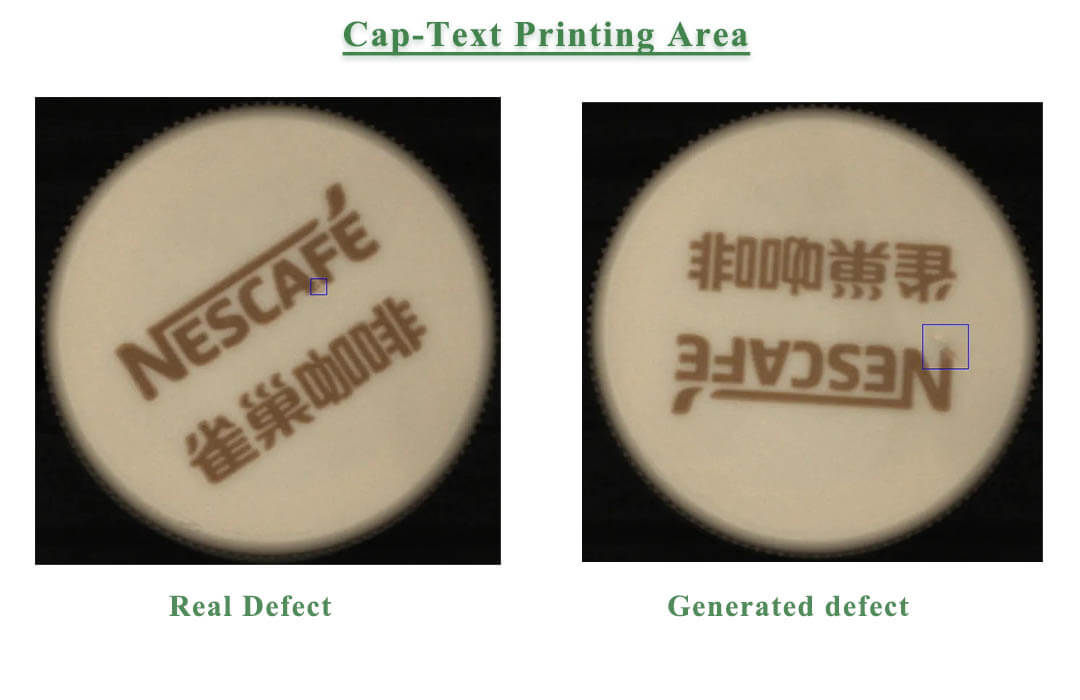

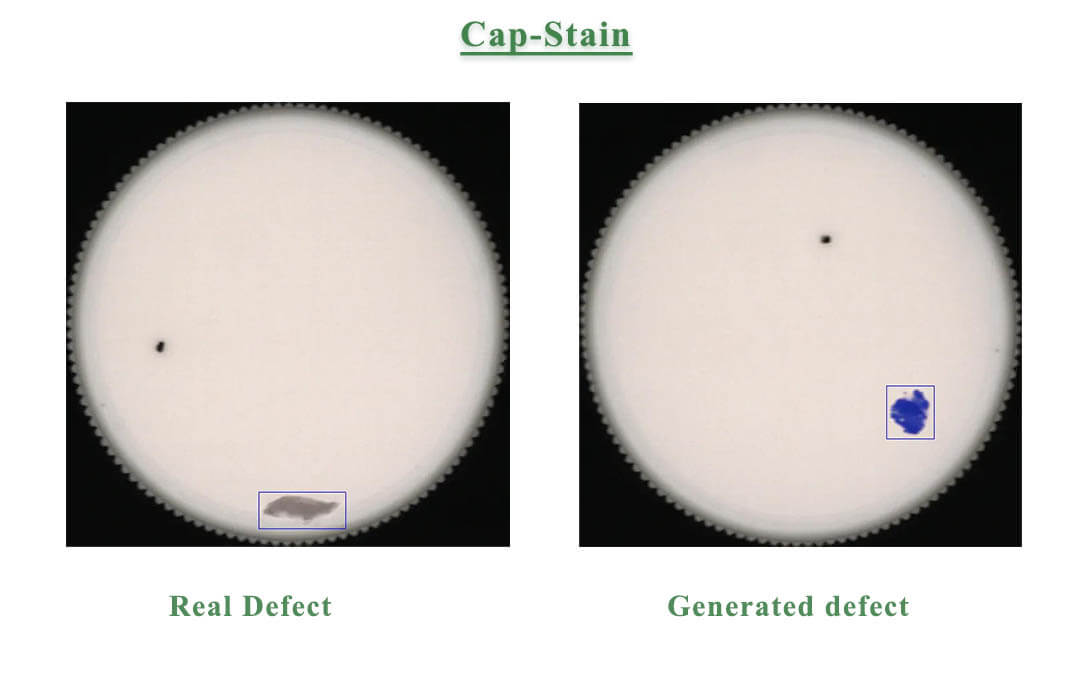

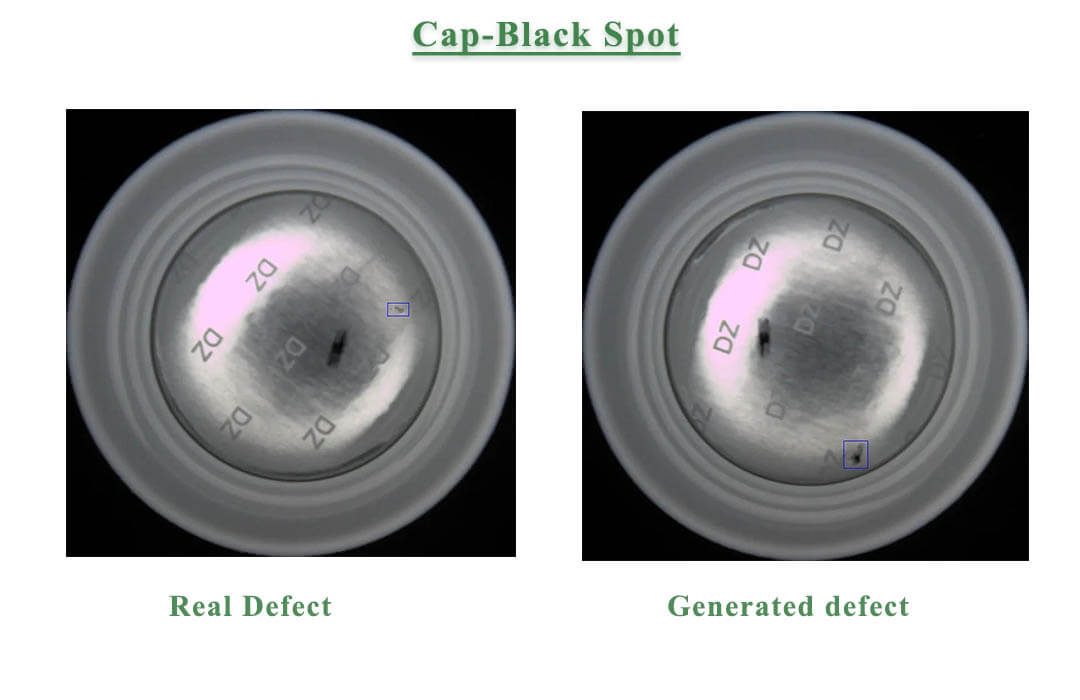

By utilizing AI and diffusion model technology, our forward and backward diffusion algorithms can simulate various types, locations, and shapes of defect images using a small number of sample images. The simulated defect images closely resemble actual defects in appearance and characteristics, providing an effective solution to the problem of insufficient defect data.

Significant Impact at Key Nodes

1.Rapid Model Construction

With limited rare defect samples, “Defect Synthesis” can generate defects, enabling quick model construction.

2.Rapid Model Deployment

When changing product types, “Defect Synthesis” can quickly generate relevant defects for model training, facilitating rapid model deployment.

3.Rapid Model Improvement

When defects are missed on the production line, “Defect Synthesis” can generate simulated defects to quickly reduce production oversights.

Intelligent and Efficient with Easy Operation

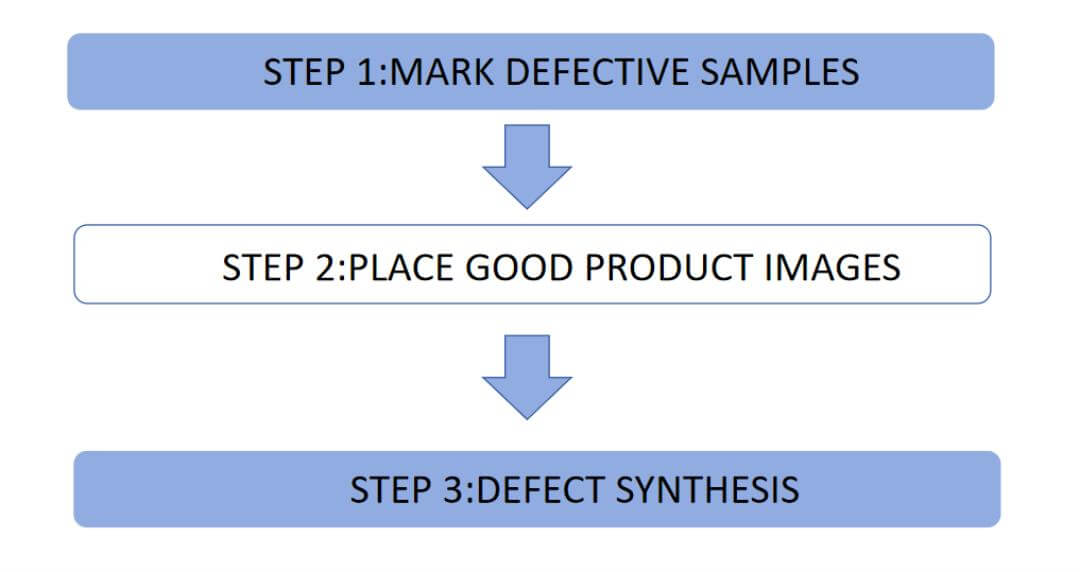

“Defect Synthesis” requires only three simple steps: marking defect samples, placing good products images, and synthesizing defects to generate a large number of high-quality defect images. This significantly shortens sample collection time and enables rapid model training.

Powerful Performance with Distinct Advantages

1.Strong Applicability

Suitable for products across multiple industries and various defects.

2.High Flexibility

Users can independently select defect locations, quantities, and types to meet personalized needs.

3.Convenient Operation

Generate defect images in three steps, greatly saving time and costs.

4.High Collaboration

Generated results come with annotation information, eliminating the need for secondary labeling and allowing direct use for model training.

5.Excellent Results

Generated defects closely resemble real defects, significantly enhancing model training effectiveness.

Efficient Generation of Simulated Defects

Generative AI plays a vital role in the field of industrial vision. Through intelligent defect generation technology, KeyeTech can quickly produce a large number of realistic defect images, solving the challenges of scarce defect samples and time-consuming collection, thereby greatly improving the training efficiency and generalization ability of AI models!