Session 5 | Theory + Practice! Transforming You from a Beginner to an Expert!

From November 4th to 8th, a five-day offline skills training event for AI visual inspection system maintenance engineers was successfully held at Keye Technology’s facility. The training course adopted a “3+2” model, combining theory and hands-on practice, aimed at enabling employees to proficiently operate and utilize the equipment.

At the beginning of the event, Wang Min, the Marketing Director of Keye Technology, warmly welcomed the participants and expressed hope that each attendee would become a specialized technical talent, contributing their skills to enhance the production quality of their companies. This, in turn, would drive the empowerment and upgrading of their enterprises. Following this, all participants toured the headquarters of Keye Technology, gaining firsthand insight into the company’s commitment to product quality and technological innovation.

Since the upgrade of its products to edge computing units, Keye Technology has had nearly a thousand devices operating stably at customer sites. Compared to traditional systems, the edge computing units offer greater computing power and stability. This training course was opened based on our product delivery status and algorithm upgrades, implementing the “3+2” model, which includes three days of algorithm training and two days of mechanical operation training.

During the AI visual inspection system training, adhering to the principle of “learning by doing,” a diverse teaching approach was employed, including “theoretical lectures + hands-on practice + practical assessments + interactive discussions.” Courses covered the use of the latest algorithm models (good product training algorithms), product changeovers, system operations, and mechanical adjustments, helping participants truly master the skills needed for using, maintaining, and troubleshooting AI visual inspection equipment.

Throughout the AI visual inspection system training, instructors conducted in-class tests and strict assessments at various stages to identify and address any gaps in knowledge, ensuring that each participant mastered the technical skills necessary to handle both software and hardware issues proficiently.

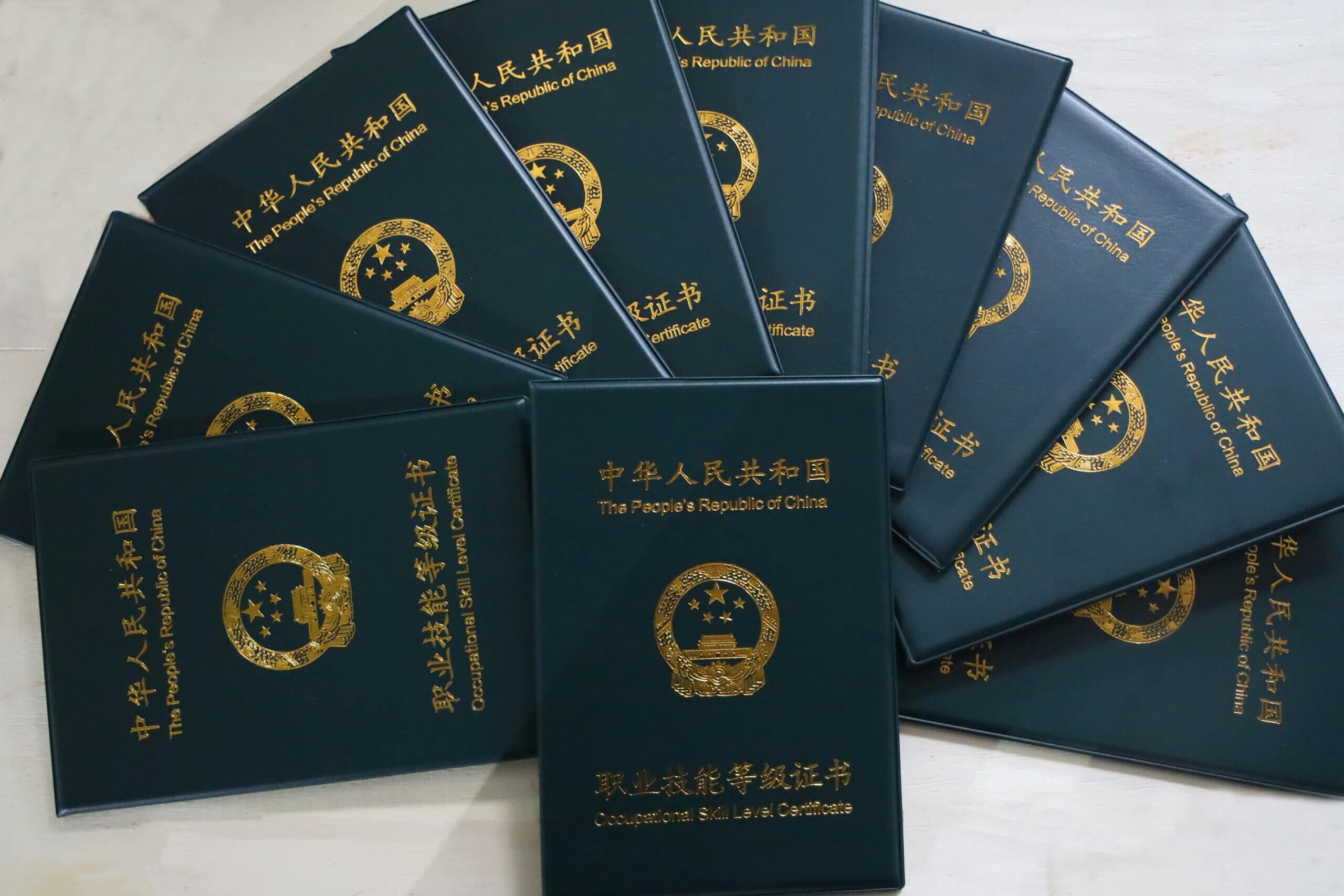

“Challenges reveal courage, and perseverance leads to success!” After five days of professional, targeted, and scientific instruction, the fifth session of the AI visual inspection system maintenance engineer offline skills training concluded successfully. Participants underwent multiple skill assessments and were awarded vocational skill certificates, enabling them to work confidently and ensuring worry-free production for their companies!

Keye Technology, with technology as its driving force, has successfully conducted multiple offline skills training sessions, setting industry benchmarks. We have trained over 200 mid- to senior-level technicians with professional skills in operating AI visual inspection system, injecting strong momentum into the visual inspection industry, significantly enhancing production efficiency, and effectively promoting enterprise empowerment and development. In the future, Keye Technology will continue to hold offline AI visual inspection system skills training events for AI visual equipment maintenance engineers, actively fulfilling corporate responsibilities and assisting clients in their empowerment and upgrades. We look forward to your participation!