Inspection Theory

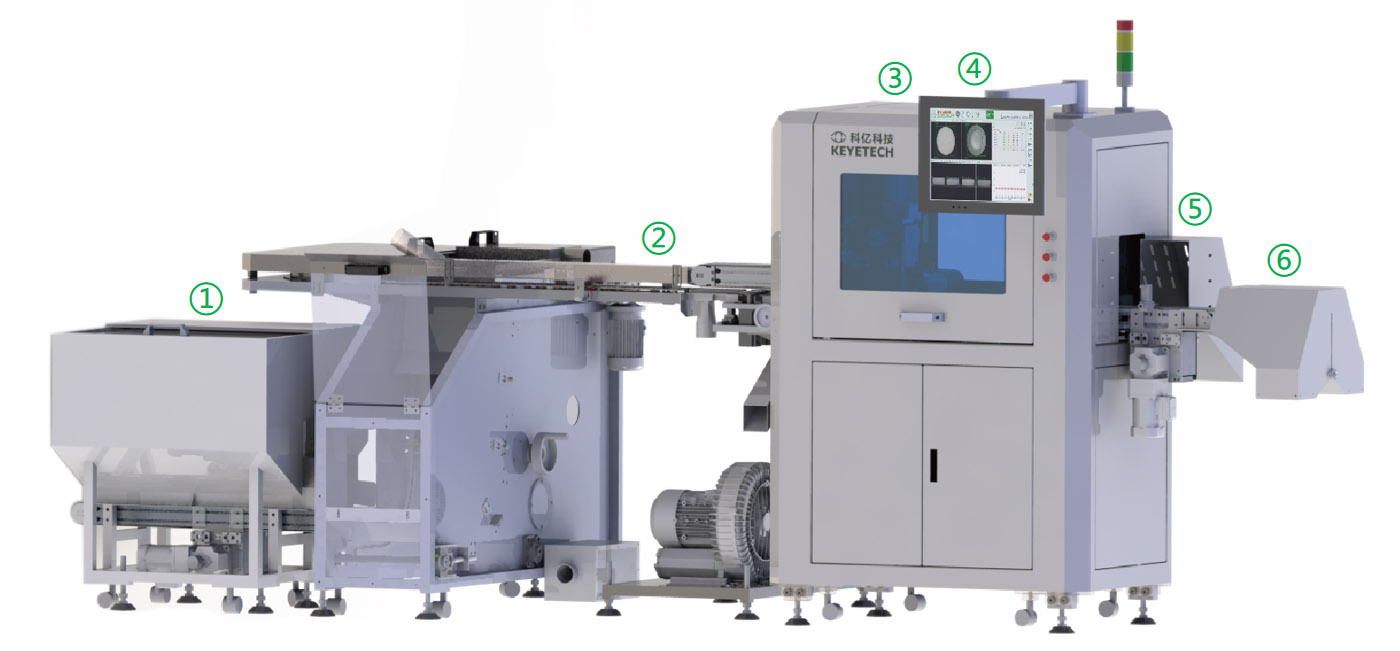

① Material Feeder ② Air conveyor belt ③ Inspection part ④ Touch screen interface ⑤ Air nozzle rejection ⑥ Counting&Packaging

Main characters

- The Latest advanced AI algorithm

- Modularization embedded processing unit

- Surging computing power NPU chip

- Cloud platform for remote operation&maintenance

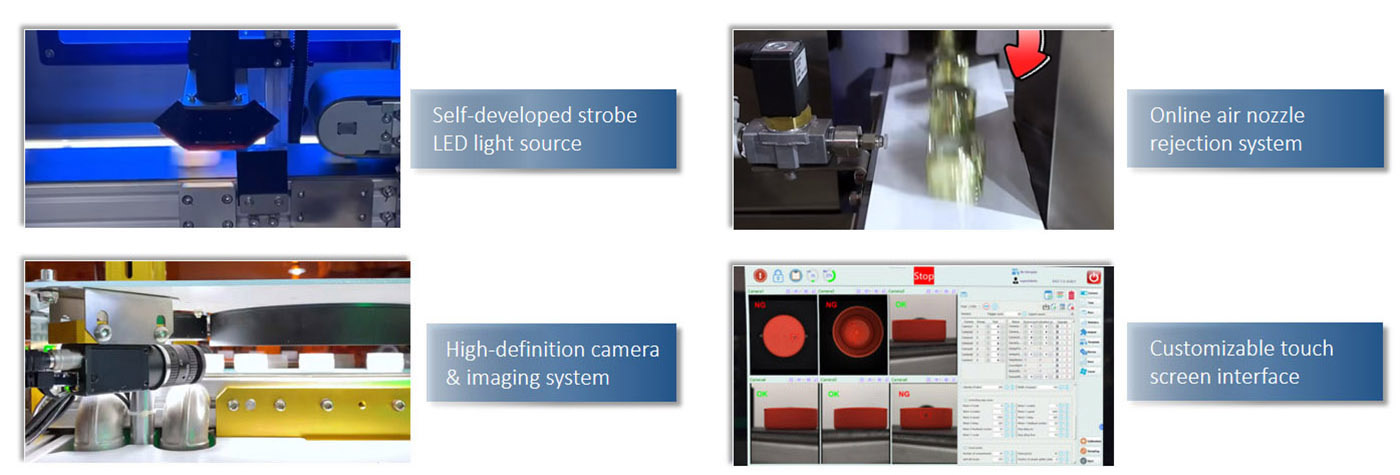

- Self-developed hardware and software system

- High compatibility with various product kinds

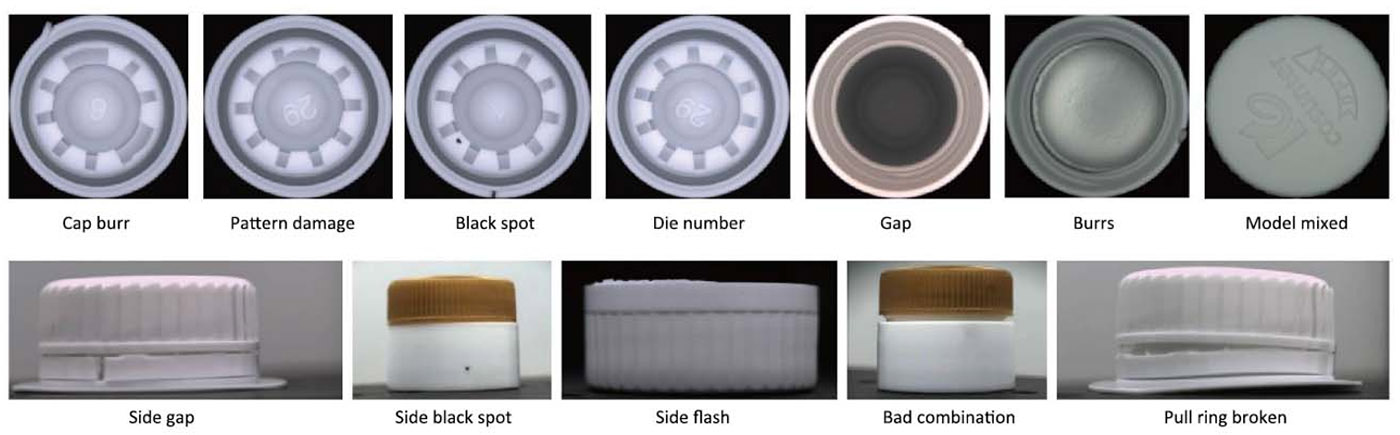

Inspection Defect Type

The intelligent AI camera visual system can perform full areas comprehensive inspection on the appearance defects of products, including conventional defects black spot, crack, thread, flash, short shot, deformation, etc.

Main Parameters

| Defect type | Appearance defects | Accuracy | >99% |

| Defect position | 360° | Power | 3~6Kw |

| Air compression | 0.5~0.8Mpa | Dimension | 3700*1300*1785mm |

| Inspection speed | 300~2500pcs/min | Weight | 700Kg |

Why Choose Us?

- Invest in our camera visual system to ensure the highest quality standards for your plastic caps, ultimately improving product reliability and customer satisfaction.

- Camera visual system is more efficient, stable, and less susceptible to environmental interference compared to traditional manual inspection.

- The strong talent advantage can meet the needs of independent research at various technical levels, ensuring the sustainability of technical support and after-sales service.

- AI algorithms can be compatible with a wider range of product types and defect types, saving costs for production enterprises.

- We have a strong after-sales service team, and each batch of exported equipment will have experienced technicians responsible for on-site installation and debugging. We will provide long-term online service support to customers remotely in the future.

- As a leading enterprise in the plastic packaging camera visual system, we hold the top position in terms of research and development team, shipment volume, and sales revenue. Our goal is to create the best visual brand in China and grow and develop together with you.

FAQs of lid quality inspection system

Q: What’s kind of caps can be inspected?

A: It can inspect all plastic bottle caps for water and beverage, daily product, daily chemical, pharmacy etc.

Q: What kind of defects it can inspect?

A: All the defects that can be seen by eyes is able to be inspected, it is only for appearance defect inspection.

Q: How many cameras are equipped in the machine?

A: The camera quantity is also decided by the detected defect kinds and positions.

Q: What’s the definition of the camera?

A: The definition of the camera and lens are depended on client’s precision request, i.e, 0.2mm*0.2mm, 0.5mm*0.5mm.

Q: If the camera is self-developed or buy from the professional camera producers?

A: Most of the cameras are designed and developed by ourselves, the lens and sensors are supplied by the worldwide brands.

Q: Is the cameras are the most important for the inspection?

A: Camera is one of the most important hardware of the inspection system, the AI algorithm software system is the key technology for the machine.

Q: If any new defect of the caps come out, how to solve it?

A: It’s a fully automatic AI camera visual system, you can add the algorithm of the new defect online.

Q: How to solve installation and adjustment?

A: We will send our skilled engineers to you for installation and adjustment, and customer can also send their engineers for training.

Q: Is difficult to use your machine, how to train our people?

A: The system is sophisticated while the operation is easy due to our high level AI system. We can train your people during the installation or by remote control, you can also send your technician to our company to learn, it’s free.

Q: What’s your machine’s guarantee? Can you supply the spare parts in the future?

A: We supply the one year warranty for our entire machine, 3 years warranty for hardware like the camera, lens, sensor, (If damaged by personal improper use customer need to purchase from us). We are responsible for the spare parts and maintenance for long time.

Q: What’s detailed information i need to supply to get a quote for camera visual system?

A: Customers need to supply following information to get a quote:

- How many kind of caps in total to be inspected and the pictures.

- How many different defect types need to be detected?(need samples or drawing)

- Inspected position or 360°full inspection?

- The inspection precision.

- Inline inspection or offline inspection? (inline: need a material feeder; offline: connect to your existing machine.

- What’s the request of the inspection speed?

- We need the physical samples for optical testing and mechanical design before the final quote.

See the video of this visual inspection machine in YouTube.

-2-500x500.jpg)

-1-500x500.jpg)

-500x500.jpg)