Inspection Theory

Main characters

- High pixel industrial camera

- High resolution industrial lens

- High brightness LED strobe light source

- Artificial intelligence (Al) algorithm

- High performance GPU computing processing unit

- High resolution industrial touch screen

- Customizable AI quality inspection platform

- Dual elimination system for classified elimination.

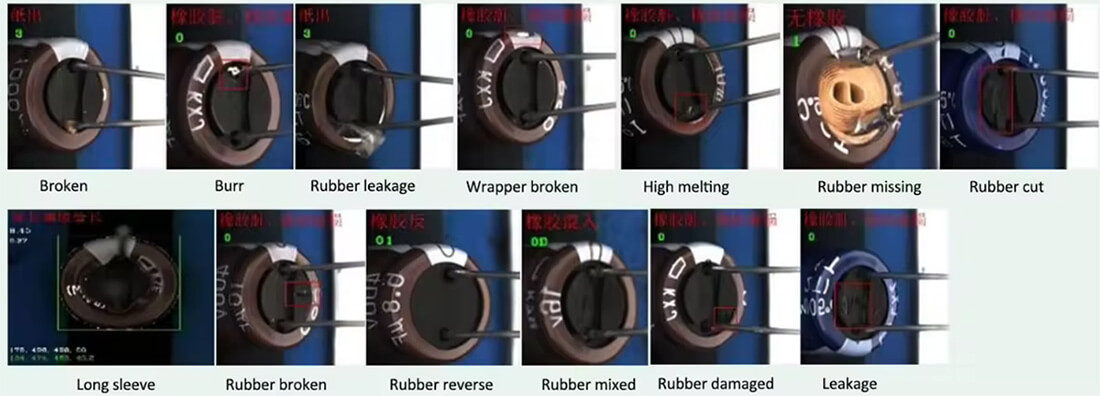

Inspection Defect Type

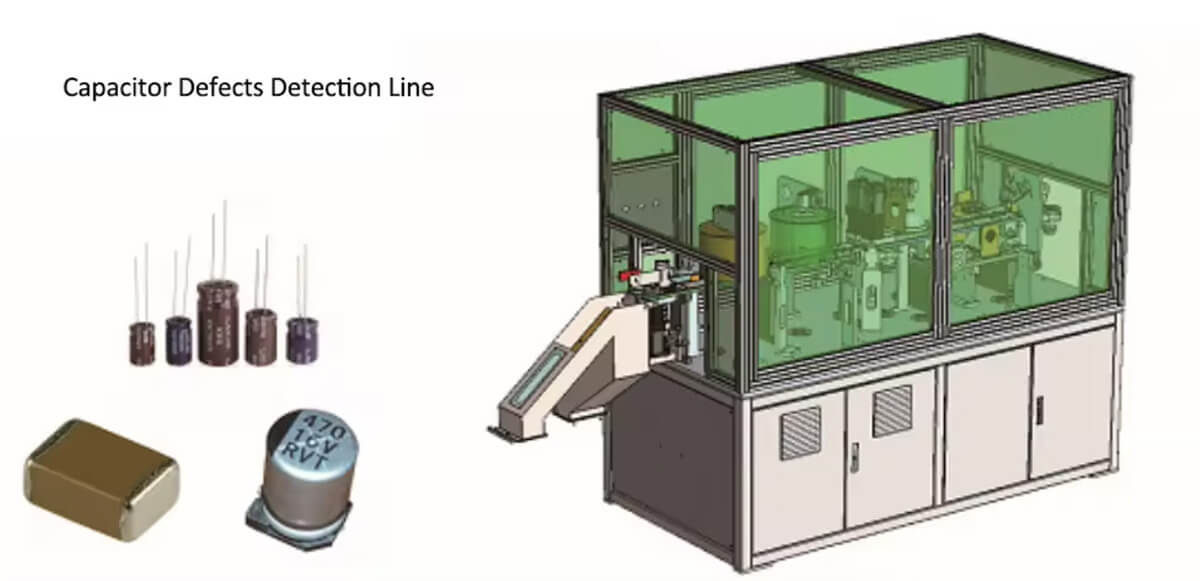

The intelligent AI capacitor visual defect inspection machine can perform full areas comprehensive inspection on the appearance defects of products, including conventional defects burr, rubber leakage, rubber broken, high melting, long sleeve, leakage, etc.

Main Parameters

| Defect type | Appearance defects | Accuracy | >99% |

| Defect position | 360° | Power | 7Kw |

| Air compression | 0.4~0.7Mpa | Dimension | 1447*1931*800mm (without feeding device) |

| Inspection speed | 300~600pcs/min | Weight | 600Kg |

FAQ

Q: What’s kind of product can be detected?

A: It can detect the vision defect of electronic component, like capacitor.

Q: What kind of defects it can inspect?

A: It can defect all the quality defects in the capacitor, including the electrode, the envelope defects.

Q: How many defects can be detected by one machine?

A: All kinds of defects can be defected, it’s depended on customer’s detection request.

Q: How many cameras are equipped in the machine?

A: The camera quantity of our this machine is 19pcs which is customized for CHEMI-CON, the exact quantity is up to the detected defect kinds and positions, the more kinds the more quantity.

Q: What’s the definition of the camera?

A: The definition of the camera and lens are depended on your defected precision, i.e, the definition is different if the defected precision is 01mm and 0.5mm.

Q: If the camera is self-developed or buy from the professional camera producers?

A: Most of the cameras are designed and developed by ourselves, especially the capacitor visual defect inspection machine is AI algorithm, the camera must match the AI system.

Q: Is the cameras are the most important for the inspection?

A: Camera is one of the most important hardware of the equipment, the AI algorithm software system is the key technology for the machine.

Q: How to solve installation and adjustment?

A: We will send our skilled engineers to you for installation and adjustment, it takes around one week.

Q: Is difficult to use your machine, how to train our people?

A: Yes, the capacitor visual defect inspection machine is sophisticated, but the control for you is easy. We can train your people online via KeyeTech AI platform which is very convenient, and you can also send your technician to our company to learn, it’s free.

Q: What’s your machine’s guarantee? Can you supply the spare parts in the future?

A: We supply the one year warranty for our entire machine, 3 years warranty for hardware like the camera, lens, sensor, (If damaged by personal improper use customer need to purchase from us). We are responsible for the spare parts and maintenance for long time.

Q: What’s detailed information i need to supply to get a quote for capacitor visual defect inspection machine?

A: Customers need to supply some exact answers to us for a quote:

- How many different model capacitors in total to be inspected?

- What’s color and size of the capacitor? (need samples or drawing)

- How many different defects need to be detected?(need samples or drawing)

- Inspect for target position or full positions?

- What’s the request of the inspection speed?

- Any special requirement for inspection precision?

- Online or offline inspection? If online how to match your capacitor making machine?

The above are part of the questions we need to discuss before the quote, for a exact quote we also need physical defect samples.

See the video of this visual inspection machine in YouTube.