High quality defect data is crucial for training and optimizing AI visual inspection models on industrial production lines. To obtain rare and high-quality defect samples for product appearance defect detection, multiple layers of effort are required.

- Artificially creating product defect samples – low authenticity!

- High yield rate and low defect rate, online collection of defect samples – time-consuming!

- Product changeover, collecting a large number of defect samples in a short period of time – difficult!

- Sample defects are complex and diverse, and collection is cumbersome – low efficiency!

Defect Generation

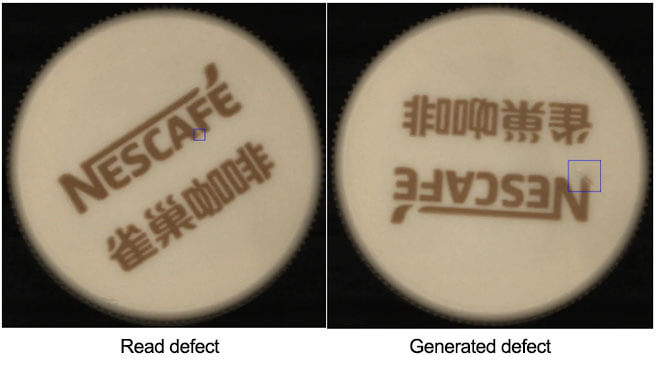

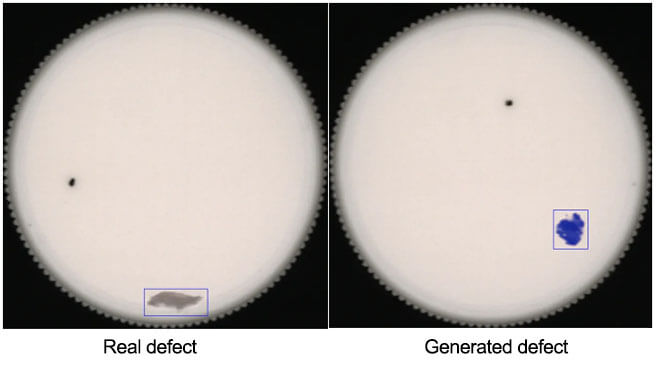

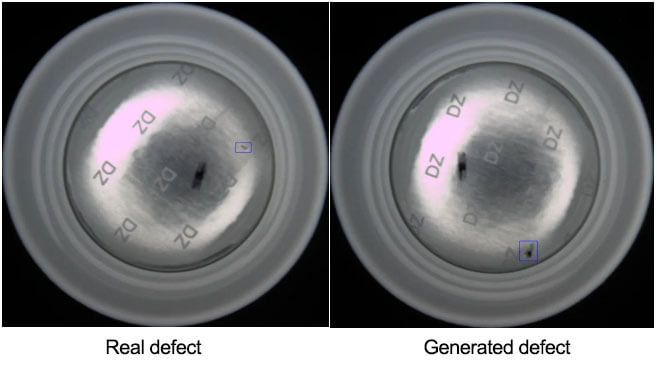

By using AI visual inspection and diffusion modeling techniques, various types, positions, and shapes of defect images can be simulated with only a small number of sample images through forward and backward diffusion algorithms. Simulated defect images are highly similar in appearance and features to actual defects, providing an effective solution to the problem of defect data scarcity.

Significant role of key nodes

- Rapid model construction

Rare defect samples are few, and defects can be generated through “defect synthesis” to achieve rapid model construction in AI visual inspection.

- Rapid deployment of models

Product changeover can utilize “defect synthesis” to quickly generate defects in related products for model training and rapid deployment.

- Rapid improvement of the model

When there are missed defects on the production line, simulation defects can be generated through “defect synthesis” to quickly reduce production missed defects.

Intelligent, efficient, and easy to operate

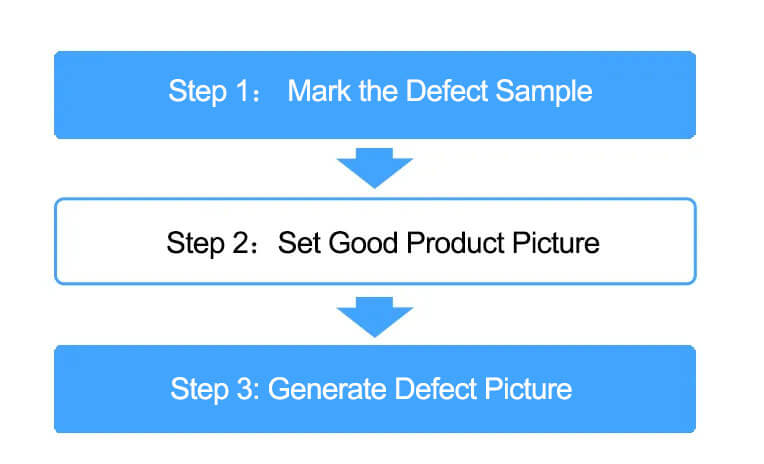

Defect synthesis “only requires three steps of marking defective samples, placing good products, and defect synthesis to generate a large number of high-quality defect maps, expand the training sample set, significantly shorten sample collection time, and achieve fast model training.

Strong performance and outstanding advantages

- Strong applicability- Can be used for products and different defects in multiple industry sectors

- Strong flexibility- Independently choose defect location, quantity, and type to meet personalized user needs

- Easy to operate- Three step generation of defect maps, significantly saving time and cost

- High Collaboration- The generated results come with annotation information, without the need for secondary annotation, and can be directly used for model training

- Excellent effect- The generated defects are highly similar to real defects, greatly improving the training effectiveness of the model in AI visual inspection field.

Efficient generation of simulation defects

Bottle cap: logo print

Bottle cap: stains

Bottle cap: black spot

Generative AI plays an important role in the field of industrial vision. Through intelligent defect generation technology, KeyeTech Skill quickly generates a large number of defect images that are close to reality, solving the problem of scarce defect samples and time-consuming and laborious collection, greatly improving the training efficiency and generalization ability of AI visual inspection model!

Click here for more AI VISUAL INSPECTION VIDEOS