Global Packaging Top Company: Menshen Packaging’s Global CEO and China Executives Visit Keye Technology to Sign Strategic Agreement! On March 18, Hansulrich Zellmer, Global CEO of Menshen Packaging, along with Shen Xiaoyue, Director of Menshen Shanghai, and Yang Feng, Director of Menshen Guangzhou, visited Anhui Keye Information Technology Co., Ltd. (hereinafter referred to as Keye […]

Author Archives: Keyeintel

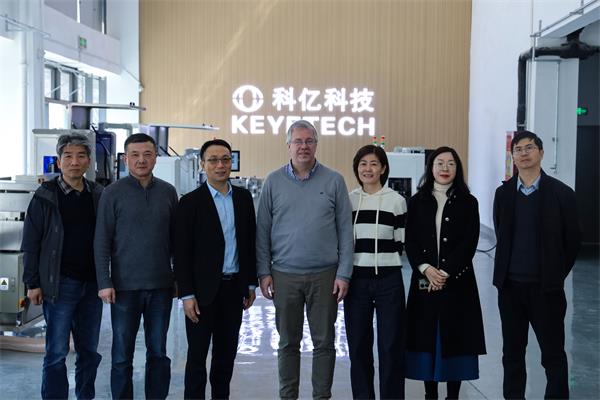

Duravant’s Key Move in the “China Intelligent Manufacturing 2030” Plan: Visit KeyeTech to Deepen Industrial Ecosystem Layout On March 3, 2025, Yu Hongtao, Director of the Chamber of Commerce of Hefei Municipal Council for the Promotion of International Trade, accompanied senior executives from Duravant, a global leader in automation and intelligent equipment manufacturing, including Jack […]

KeyeTech Awarded the Title of “Outstanding Supplier” by CHEMI-CON in AI Visual Inspection Field Recently, Anhui Keye Information Technology Co., Ltd. (hereinafter referred to as KeyeTech) was honored with the title of “Outstanding Supplier” by CHEMI-CON(Wuxi) Co., Ltd. (hereinafter referred to as CHEMI-CON) for its exceptional technical capabilities and high-quality services in AI visual inspection […]

Exciting News | Keye Technology Headquarters Relocates to a New Address! A new chapter begins with vibrant colors, as the auspicious dragon and phoenix dance gracefully. On December 28th, at a propitious time, the relocation celebration of Keye Technology’s headquarters was grandly opened in the High-tech Zone,Hefei city. The company’s chairman, along with all employees, witnessed this […]

Session 5 | Theory + Practice! Transforming You from a Beginner to an Expert! From November 4th to 8th, a five-day offline skills training event for AI visual inspection system maintenance engineers was successfully held at Keye Technology’s facility. The training course adopted a “3+2” model, combining theory and hands-on practice, aimed at enabling employees […]

KeyeTech Core Technology of Industrial Vision Inspection AI 2.0 Era – “Good Product Training Model” Keye Technology leads innovation, based on two modules of deep learning, supervised and unsupervised, combined with practical experience, to independently develop the core technology of Industrial Vision inspection AI 2.0 era – “Good Product Training Model”. It is divided into anomaly inspection and […]

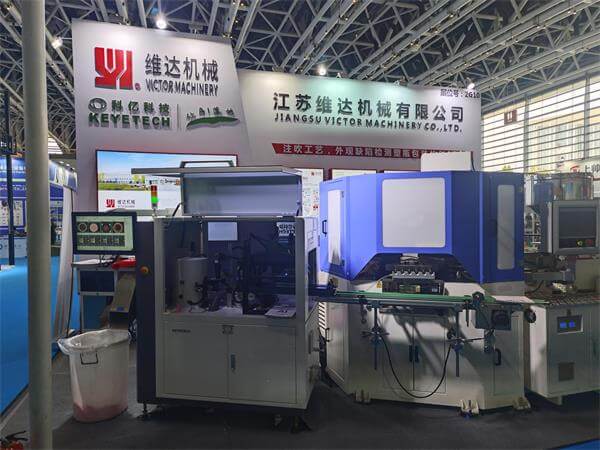

Exhibition | Victor Machinery and Keye Technology Join Hands to Meet at the API International Pharmaceutical Exhibition in Golden Autumn October! In Golden Autumn October, Xi’an, China.The 91st China International Pharmaceutical Raw Materials/Intermediates/Packaging/Equipment Trade Fair grandly opens at the Xi’an International Convention and Exhibition Center.Victor Machinery and Keye Technology make a joint appearance.Exciting moments not to be […]

Visual Inspection Machine in the Pharmaceutical Industry | KeyeTech’s Eight Self-Developed Core Technologies Era of Industry 4.0 In the era of Industry 4.0, various sectors in our country are experiencing modernization and intelligent development trends. The demand for visual inspection machine to achieve high automation, high precision, and high efficiency is becoming widespread, especially in […]

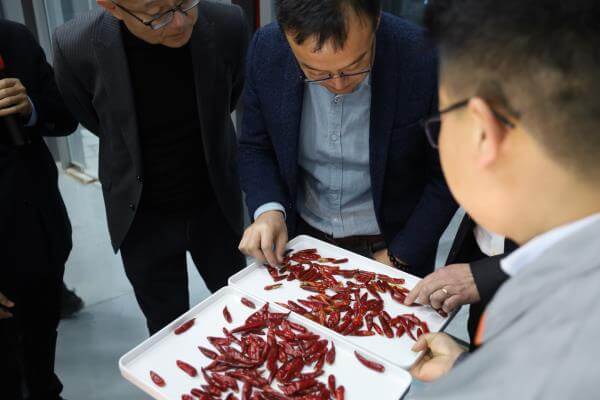

High quality defect data is crucial for training and optimizing AI visual inspection models on industrial production lines. To obtain rare and high-quality defect samples for product appearance defect detection, multiple layers of effort are required. Artificially creating product defect samples – low authenticity! High yield rate and low defect rate, online collection of defect […]

Exciting Launch! KeyeTech Achieves New Breakthrough in Defect Generation In industrial production lines, high-quality defect data is crucial for training and optimizing AI visual inspection models. Obtaining rare, high-quality defect samples for product appearance defect detection requires multi-layered efforts. is an inevitable trend. Manually creating product defect samples—low authenticity! High yield rates and low defect […]

- 1

- 2