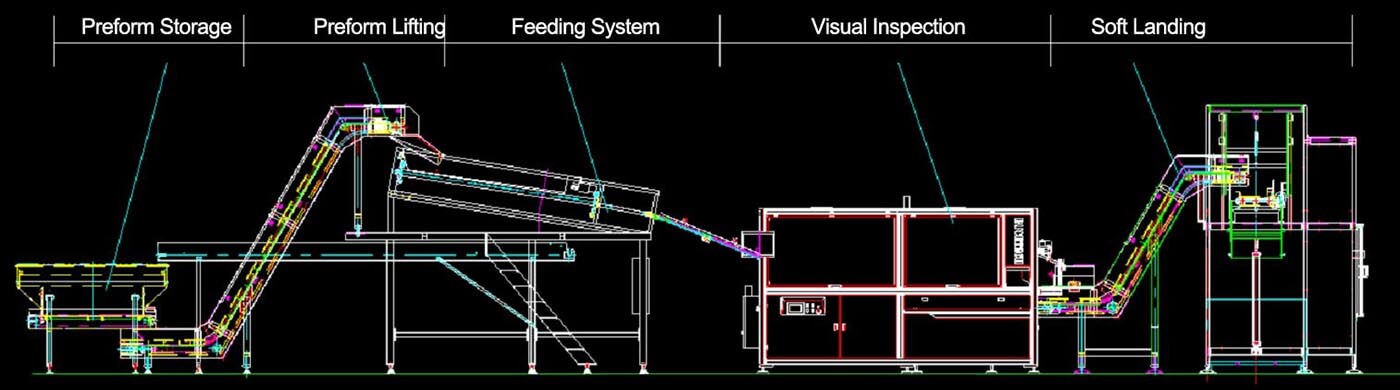

Fully Automatic Preform Inspection Machine Production Line

The preform inspection machine is the most important part in quality control of preforms. In a modern preform detection production line, it needs to include automatic dumper, preform storage system, lifting machine, embryo feeding machine, visual inspection machine, and conveyor line. Each preform manufacturer can choose personalized equipment configuration according to automation requirements, but visual inspection as the core machine is a must. The following is an introduction to our company’s latest preform inspection system.

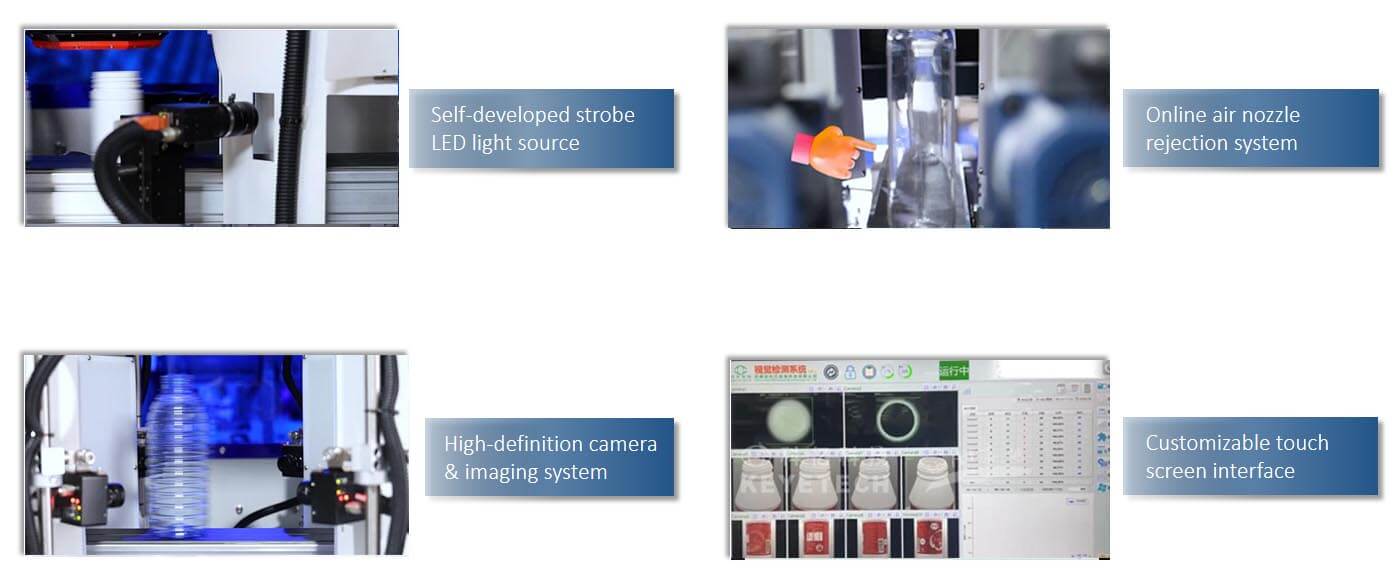

Inspection Theory

Main characters

- The Latest advanced AI algorithm

- Modularization embedded processing unit

- Surging computing power NPU chip

- Cloud platform for remote operation&maintenance

- Self-developed hardware and software system

- High compatibility with various product kinds

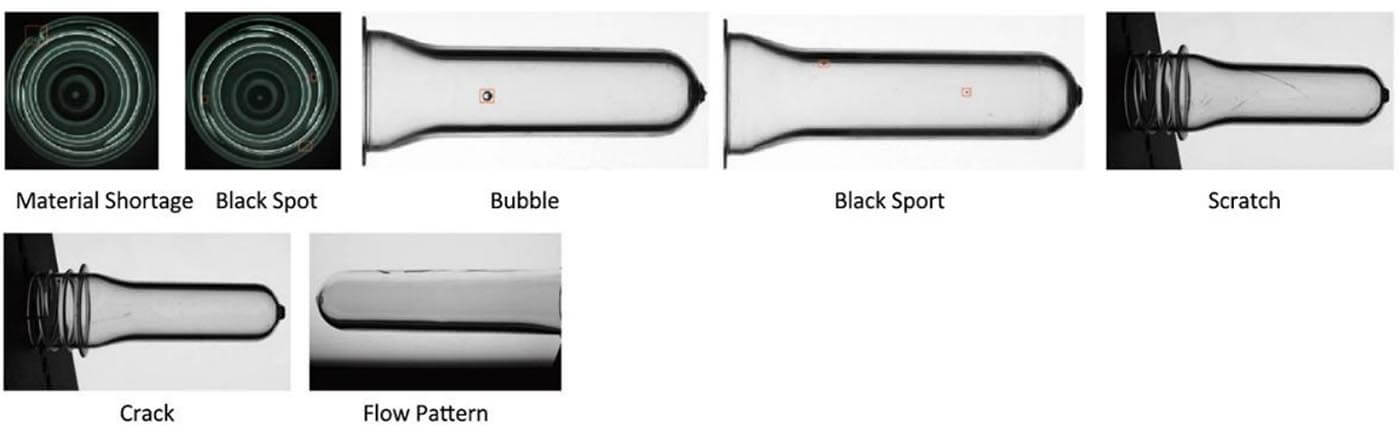

Inspection Defect Type

The 10 camera preform inspection machine can execute full area comprehensive inspection on the appearance defects of preforms, including conventional defects black spot, crack, thread, flash, short shot, deformation, etc.

Main Parameters

| Defect type | Appearance defects | Accuracy | >99% |

| Defect position | 360° | Power | 3~7Kw |

| Air compression | 0.5~0.8Mpa | Dimension | 3700*1300*1785mm |

| Inspection speed | 150~600pcs/min | Weight | 500Kg |

FAQs of Preform Inspection Machine

Q: What’s kind of preforms can be inspected?

A: It can inspect all PET/PE preforms.

Q: What kind of defects it can inspect?

A: The system is only for appearance defect inspection.

Q: How many cameras are equipped in the machine?

A: The camera quantity is also decided by the detected defect kinds and positions.

Q: What’s the definition of the camera?

A: The definition of the camera and lens are depended on client’s precision request, i.e, 0.2mm*0.2mm, 0.5mm*0.5mm.

Q: If the camera is self-developed or buy from the professional camera producers?

A: Most of the cameras are designed and developed by ourselves, the lens and sensors are supplied by the worldwide brands.

Q: Is the cameras are the most important for the inspection?

A: Camera is one of the most important hardware of the inspection system, the AI algorithm software system is the key technology for the machine.

Q: How to solve installation and adjustment?

A: We will send our skilled engineers to you for installation and adjustment, and customer can also send their engineers for training.

Q: Is difficult to use your machine, how to train our people?

A: The system is sophisticated while the operation is easy due to our high level AI system. We can train your people during the installation or by remote control, you can also send your technician to our company to learn, it’s free.

Q: What’s your machine’s guarantee? Can you supply the spare parts in the future?

A: We supply the one year warranty for our entire machine, 3 years warranty for hardware like the camera, lens, sensor, (If damaged by personal improper use customer need to purchase from us). We are responsible for the spare parts and maintenance for long time.

Q: What’s detailed information i need to supply to get a quote?

A: Customers need to supply following information to get a quote:

- How many kind of preforms in total to be inspected and the pictures.

- How many different defect types need to be detected?(need samples or drawing)

- Inspected position or full area inspection?

- The inspection precision.

- Inline inspection or offline inspection? (inline: need a material feeder; offline: connect to your existing machine.

- What’s the request of the inspection speed?

- We need the physical samples for optical testing and mechanical design before the final quote.

See the video of this visual inspection machine in YouTube.