Visual Inspection Machine in the Pharmaceutical Industry | KeyeTech’s Eight Self-Developed Core Technologies

Era of Industry 4.0

In the era of Industry 4.0, various sectors in our country are experiencing modernization and intelligent development trends. The demand for visual inspection machine to achieve high automation, high precision, and high efficiency is becoming widespread, especially in the pharmaceutical industry. Pharmaceutical companies are facing increasingly stringent requirements regarding processes, environments, and product quality. Drug safety has become one of the key concerns for relevant government departments and the public.

Visual inspection machine technology has extensive applications in drug packaging, quality inspection, and control. KeyeTech has applied visual inspection machine technology in areas such as empty bottle inspection, bottle caps and inner components, liquid level and sealing, and bottle labeling and coding. By combining our in-house AI algorithm team, we extensively utilize deep learning in the field of visual inspection. Through convolutional operations, we train small sample sizes to generate the most suitable inspection models for products, achieving broader inspection coverage and higher equipment operational efficiency. This supports the pharmaceutical industry in accelerating modernization and intelligent processes, meeting the strict quality control requirements of pharmaceutical products.

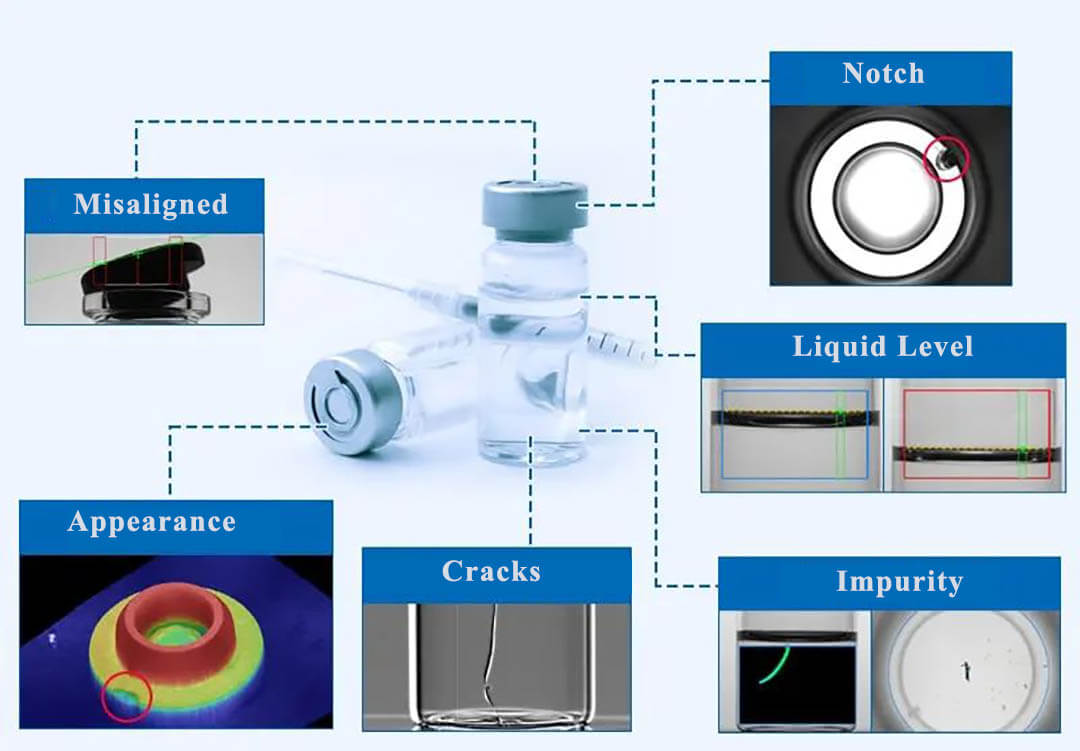

01 Application Scenarios

Empty Bottle Inspection

* Detection of damage and cracks on the bottle mouth, neck, body, and bottom, as well as defect area.

* Measurement of inner and outer diameters, ovality, diameter differences, etc.

* Detection of white and black particulates, hair, colored fibers, etc.

Bottle Caps and Inner Components Visual Inspection

* Checking for the presence of inner components, deformation, damage, and contamination of bottle caps and inner parts.

* Detection of white and black particulates, hair, colored fibers, etc.

Liquid Level and Sealing Inspection

* Standard liquid levels can be set to detect deviations.

* Checking for unsealed caps, misaligned caps, scratches, contamination, and thickness variations.

Bottle Labeling and Coding Inspection

* Detection of the presence of labels and codes, wrinkles, changes in length and width, misalignment, and height differences on both sides.

02 Eight Self-Developed Core Technologies

AI Algorithm System

* Comprehensive AI algorithm system: deep learning algorithms for defect visual inspection, classification, measurement, and enhancement

* Small sample training to refine algorithm network models for high precision and real-time recognition

Next-Generation Human-Machine Interaction Control System

* Ergonomically designed UI for simplicity and ease of operation

* Rich statistical information supporting central control systems

*Compatibility with various protocols for quick integration with central control and upstream/downstream devices

Optical Imaging System

* Customized LED light sources

* Three-dimensional spatial angle and intensity design for lighting and imaging

*Analysis of the relationship between light and the surface and internal characteristics of objects

Cloud-Based Training and Operation Platform

* Cloud-based adaptive training platform

* Self-optimization for user convenience and speed

* High-speed and stable proprietary servers

* Remote real-time online operation and maintenance

* 7*24 timely resolution of customer issues

High-Definition Industrial Cameras

* High speed and high resolution

* More accurate color reproduction with purer colors

* Higher contrast for precise differentiation between light and dark

Embedded Processing Platform

* High reliability, adaptable to high temperatures, humidity, dust, and vibration

* Highly integrated, low power consumption, and lower costs

Edge Computing Technology

* Modular design; easy to use and maintain; strong scalability

Optimal Comprehensive Solutions

* Focused, with over 20 years of deep expertise in the visual inspection machine field

* Professional capabilities in optical, mechanical, electrical, computing, and software design and development

*Comprehensive services covering AI algorithms, equipment, and on-site deployment

Click here for more AI VISUAL INSPECTION VIDEOS